Imported Quick Lime

Devdhar Chemicals Pvt. Ltd. is one of the largest Importers of a wide range of lime products in India, and have introduced, marketed & started supply of HIGH GRADE - IMPORTED QUICK LIME to SUGAR INDUSTRIES.

IMPORTED QUICKLIME HIGH-GRADE HAS FOLLOWING ADVANTAGES OVER CONVENTIONAL LIME

| Parameters | Observations |

|---|---|

| Sizes Available |

Two Variants are available, depending upon Particle

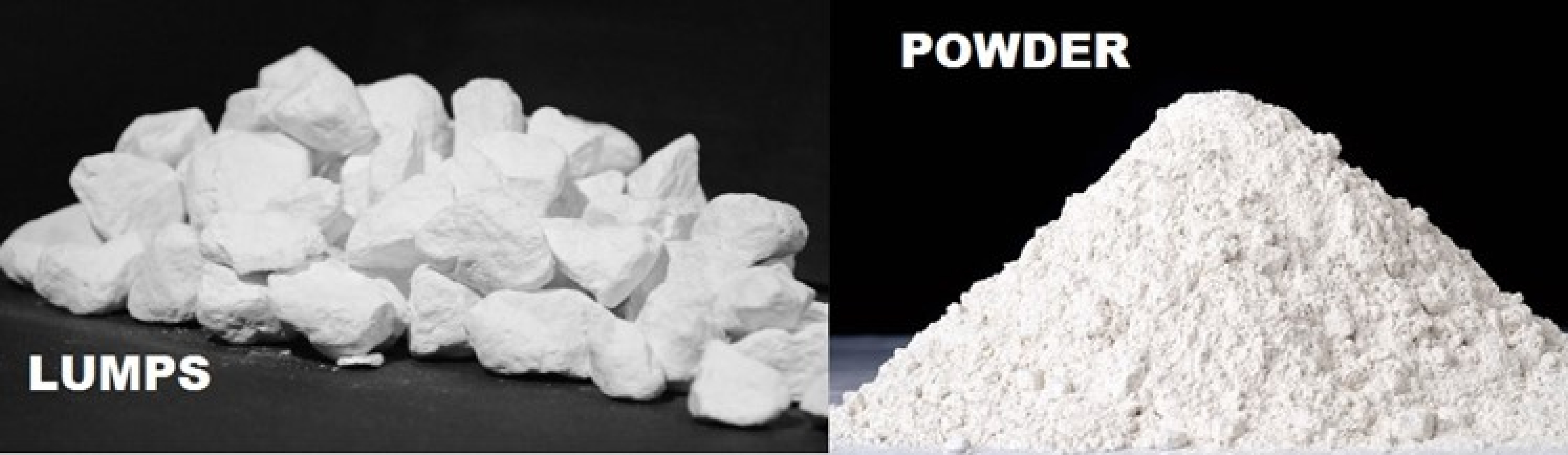

Size 1. In Lumps Form (05 to 25 mm) 2. In Powder Form (00 to 05 mm) The minimum particle size ensures maximum reactivity, i.e. Smaller the particle - Higher the reactivity |

| Higher CaO Percentage (Purity) |

Total CaO - 92% to 96% Available CaO - 90% (Min.) |

| Lower Impurities Present |

NO / MINIMAL PRESENCE of Silica (SiO2), Alumina (Al2O3),

Iron (Fe2O3) MgO - 2% to 3% Trace Elements like Sulfur, Manganese - Forming Approx. 0.5% to 1% Part |

| Lowest GRIT / Unburnt |

Approx. 1% to 2% - In Lumps (00 to 25 mm) Nil. Or 0% - In Powder Form (00 to 5mm) |

| Lower Consumption Per 1 Lac Cane Crushing |

Approx. 100 MT (In Range of 95 MT to 105 MT) |

| Results of Study on Evaporator Body Scale Formation |

Minimal Scaling due to low or no presence of

impurities. Cleaning can be processed at an interval of 30 to 45 day’s straight run, with full capacity. |

| Increase In Sugar Grain Size Observed |

As minimal scaling, the effective heating of Melt is

higher, which results in GROWTH of Grain Size in given

batch retention time. i.e. Production of "S" size sugar is quite LESS (Approx. 50%), with comparison to "M" (Aprrox. 20 to 30%) & with some qty of "L" Approx. 10 to 30% or more). |

| Improvement In Sugar Color - ICUMSA |

From : 90 to 110 ICUMSA Units To : 60 to 70 ICUMSA Units |

This Lime is manufactured using PURE NATURAL GAS as a FEUL, in D Shaped, Twin Shaft and Parallel Flow Regenerative Kiln, which has been designed and engineered by the leading Lime Kiln provider in the world. These are one of the most efficient Kilns in the market, which ensures uniform quality, and continuity of production.

Here at DEVDHAR CHEMICALS we make sure that our materials are thoroughly tested before the product is shipped to our customers, thus ensuring that the exact quality desired by the customer is dispatched.

PRODUCT:

Quick Lime is made by the thermal decomposition of limestone, that contains calcium carbonate (CaCO3). A Lime Kiln heats the material to above 825 °C. This process releases carbon dioxide (CO2) and leaves behind Quick Lime.

CaCO3(s) → CaO(s) + CO2(g)

Approximately 1.8 MT of Limestone is required to produce 1.0 MT of Quick Lime

TYPICAL PRODUCT SPECIFICATION:

| Available Calcium Oxide (CaO) | 90% Min. |

| Total Calcium Oxide (CaO) | 92.5% Min. |

| Silicon Dioxide (SiO2) | 1% Max. |

| Magnesium Oxide (MgO) | 1.5%% Max. |

| Sulphur (S) | 0.04% Max. |

| Aluminium Oxide (Al2O3) | 0.2% Max. |

| Iron/Ferric Oxide (Fe2O3) | 0.2% Max. |

| Loss On Ignition LOI @ 1000oC | 4.0% Max. |

MARKET:

Quick Lime finds broad acceptance in applications like Steel Industry, Paper Mills, Sugar Industry, Construction, Aluminium Industry, Flue Gas treatment, Agriculture, Food & Feed markets, Glass, etc. Thus touching upon many aspects of our every-day life. We are currently supplying to Sugar, Steel, Paper and Chemical Industry.